“I’ll be back”. How many of you recall the first time you watched the T-800 (or the Terminator)? In 1984, James Cameron turned Arnold Schwarzenegger into an android, forever changing the way we perceive robots. In 1968, Stanley Kubrick had already introduced us to HAL 9000 in 2001: Space Odyssey; George Lucas, in 1977, introduced the best pair of robots ever: R2-D2 and C-3PO. We have come a long way; many science fiction films and books later, Iron Man is today’s reference of excellence when it comes to robotics.

Those who visit iiLab – INESC TEC Industry and Innovation Laboratory know, from the get-go, that this is not what they will find. But, beware! The lab does not develop robot vacuum cleaners. Let’s talk about innovative robotic solutions adapted to the industry, capable of addressing the growing challenges of the sector. There are robotic arms and mobile robots, there is Artificial Intelligence (AI) and augmented reality, there is room for experimentation and training. But there is, above all, science – and, with it, many ideas. So, we’re not that far away from other robots that have stolen our hearts, like WALL-E. Shall we embark on this journey together?

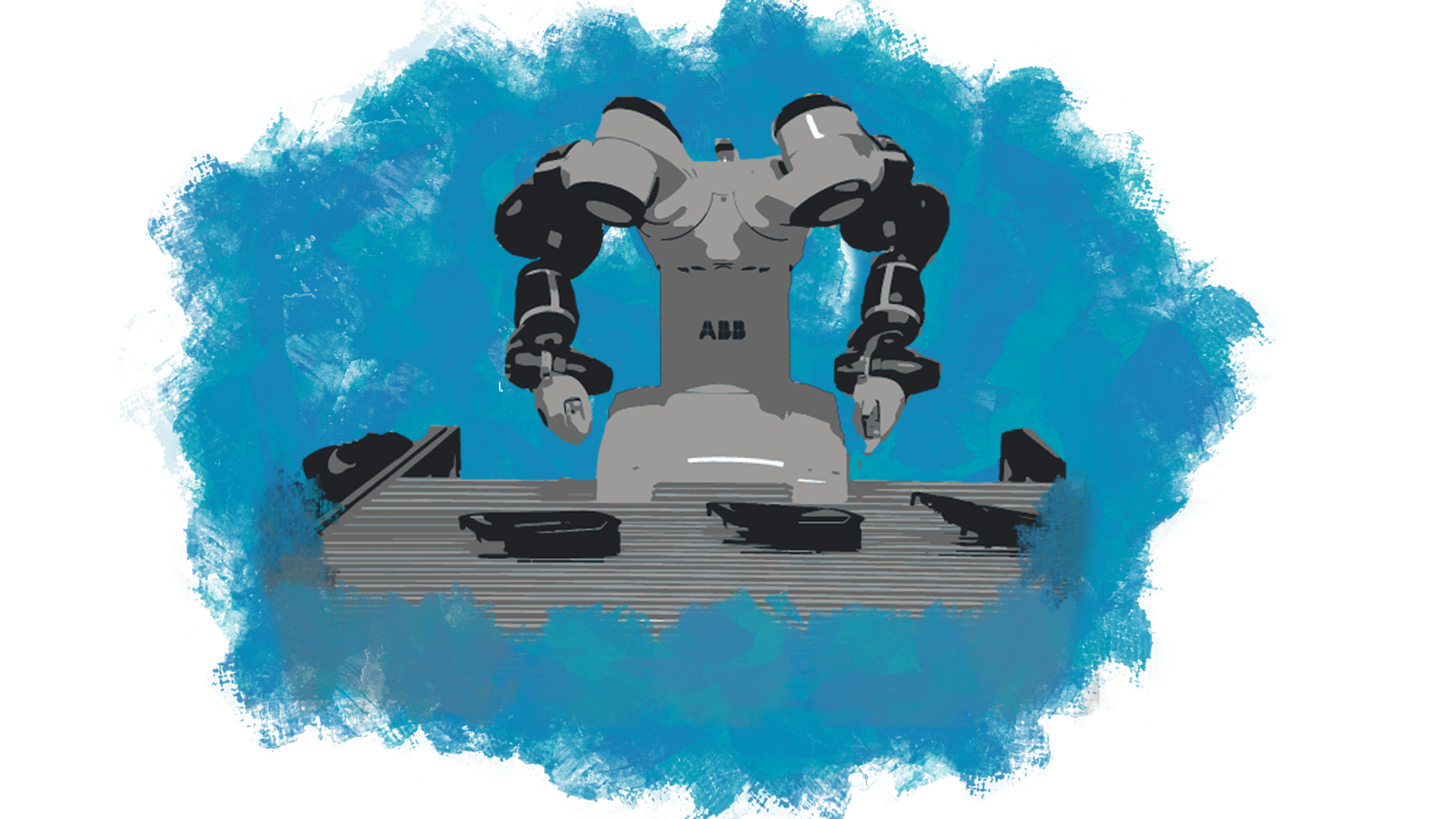

The environment is one of constant movement. Researchers gather around robots or (be amazed!) a computer full of algorithms, towards changing the world. This is a space for demonstration and dissemination, where robots are not the only stars. In addition to the scientific and innovation component, this laboratory also acts as a learning factory where it is possible to train and test prototypes. Luís Rocha and Héber Sobreira are the maestros of this orchestra, but each one controls the rhythm of their own section. While Luís is responsible for the robotic manipulators, Héber is the leader of the mobile robots. Let’s talk about numbers: close to 30 people work at iiLab. There are a dozen different robotic demonstrators and eight test pieces of equipment. 90% are collaborative robots. The solutions? Infinite.

Have robots come to replace us?

Industry 4.0. showed companies the need to adopt technology and create machine-to-machine and machine-to-system communication mechanisms. With the arrival of industry 5.0, the focus shifted towards people. There is an increasing lack of qualified operators. According to the Organisation for Economic Co-operation and Development (OECD) study Employment Outlook 2023, 27% of jobs in Europe will be affected by digital transformation and are highly likely to be automated. In Portugal, this percentage rises to 30%. “This paradigm shift will force companies to upskill (acquire new skills) and reskill (retrain) their workforce in order to optimise human-machine interaction in assembly and production environments. It can be difficult to accept this change. We will no longer have people working in repetitive processes with low technological density – they’ll take on duties that require greater creative and intellectual abilities. Because, at least for now, this is what set us apart from machines: we add value to the products”, stated Luís Rocha.

But what kind of robots are we talking about? At iiLab, almost every robot is collaborative: they share the space with the operators, without the need for additional safety measures in the first place. However, the choice between conventional or collaborative robotics solution (and the respective safety measures) must be evaluated on a case-by-case basis. One of the demonstrators that iiLab is working on is a collaborative mobile manipulator capable of picking small objects, considering a logistics warehouse scenario, and aggregating them into ready-to-ship kits. “This was a specific request from a company; in this case, we resort to hardware (robotic manipulator) we have since 2014, while adapting and evolving the algorithms to the needs of this concrete task. Ultimately, the rate of operation will be lower when compared to a human operator, but it has the advantage of executing it autonomously 24 hours a day, freeing operators for tasks that generate more value to the company and themselves. In fact, we already have many solutions demonstrated for a specific scenario that we can adapt – depending on the customers’ needs. The most important aspect here is knowing that to ensure top flexibility and autonomy of a robotic system – and bring greater efficiency gains – it is vital to guarantee the full integration with production management systems”, explained Luís Rocha.

Héber Sobreira explained how a robot, applied to logistics and material transportation in a label factory, added predictability to the production process, making it cheaper. “The introduction of robotics and automation will require changes in manufacturing processes, so they become more efficient. You don’t put a robot somewhere waiting for it to work for you. The robot forces the establishment of passages, which must be clear, so that the processes occur in a more standardised way, and everything is tidier and more organised. In addition, as they are connected to the factory network, it is possible to know where the products are, when they were delivered, the delivery time – automatically and immediately”. From prototype to commercial solution, Zhello, a mobile robot capable of docking, is another example of this lab’s creative ability.

Training is the path to competitiveness and innovation

Greater profitability, reduced error, increased scale capacity and greater productivity are just a few examples of the benefits of using industrial robotics. In Portugal, the industry is very traditional; there are still not many collaborative robots installed in manufacturing units. Companies (especially small and medium-sized) have not fully embraced digitalisation, either due to high investment or lack of knowledge. “In the future, there will be more automation and more robots, and workers will need to invest in new skills. INESC TEC can play an important role here, namely through its laboratories – which will act as learning factories in terms of reskilling and upskilling”, said Luís Rocha.

But you’re wrong if you think that iiLab focuses exclusively on robots. And if you’re expecting to meet scientists in lab coats, think again. The laboratory works as a test infrastructure for demonstrations of various applications, highlighting the versatility and adaptability of robotic technologies, and as a place for training and qualification of companies and skilled workforce.

“We managed to replicate the flow of a micro factory with a storage, assembly, finishing, quality control and shipping area, where we are demonstrating Industry 4.0 and 5.0 technologies, in a controlled scenario. The companies can identify themselves with the challenges and solutions we present. Moreover, they can use our infrastructure and know-how to test their products. We seek to play an important role in the preliminary testing of solutions, and even contribute to their maturity”, explained Luís Rocha.

Héber Sobreira goes further: “many companies have had robotic solutions in the past, and they did not go well. INESC TEC aims to contribute to a positive experience. There are many companies that are interested in owning robotics solutions and products, and there are problems that require adapted resources and customised robots. We can help! Most of our solutions stem from European projects, so we know the companies’ hardships”.

Our robots don’t vacuum, but they navigate!

Apart from a factory’s hustle and bustle, iiLab allows us to actually experience an industrial environment. From automated palletising to inspection of parts through artificial vision, each demonstration is a glimpse of the potential of robotics applied to this area.

In mobile robots, the secret lies in navigation. Robots must be able to locate themselves in certain spaces, coordinating movements with other robots, while avoiding obstacles. Um… doesn’t this sound familiar? “In my opinion, a robot incapable of navigating autonomously, is not a robot. People can use the argument that they already have a robot vacuum cleaner at home, which moves around. But what we do here goes far beyond robot vacuum cleaners. We already know business solutions, and we know their disadvantages. Our goal is to develop faster, more robust, and capable solutions”, mentioned Héber Sobreira.

The industrial robots we got to know are programmed to perform tasks accurately and efficiently. However, they don’t have eyes to observe what surrounds them (yet!). This is where artificial vision comes in: a technology that allows robots to “observe” and understand the environment. Imagine a robot assembling parts on a production line. It has been pre-programmed to perform a specific set of operations. However, the operator must critically supervise the process to ensure that everything is being done correctly. But what if the robot could do it on its own?

“Artificial intelligence (AI) is the key. Robotics benefit greatly from data. Companies that have process data available allow the use of AI algorithms that assist the robot, namely in planning its operation, identifying the products, adapting its trajectory and tools required. How does a robot move to pick up an object? How do we make sure it picks it up accurately? Combining models and AI intelligence, the robot will be able to take pieces it has never seen and even analyse them. Therefore, the cutting-edge technology of our robots is not visible”, said Luís Rocha.

The introduction of AI is beneficial, but it still raises many questions. “We know and understand the software, the programs and the source code because they were created at our lab. As soon as AI acquires this ability, we will no longer have control over technology, because decisions will be made completely autonomously by the machines”, added Héber. This is where the “EU AI Act” comes in – the first-ever law on AI, which aims to ensure that said systems are safe and comply with legislation. But this is the theme for another Spotlight (who knows?).

Creative robots: myth or reality?

The introduction of robotics in the industry stems from the need to mass produce (performing repetitive processes to exhaustion). Today, we move in the opposite direction. We have entered the era of customisation. Robotics is no longer limited to more traditional sectors, e.g., automotive. The shipbuilding and construction industries, the textile and footwear sectors, are some of the areas where robotics is beginning to gain ground.

“Digitalisation is vital to robots, so they can understand the tasks they must perform, while recognising the products on a given workstation, and receiving/giving orders automatically. However, some processes cannot be automated; and robots are still incapable of personalising products”, said Luís Rocha. Returning to the textile sector: can a robot sew? “There are highly sophisticated sewing machines, and the operator only needs to provide raw material. But the robot cannot replace the human hand in this simple action, nor can it manipulate flexible materials. Robotics is not yet mature enough to enter the textile area and there is still a long way to go”.

Héber Sobreira stated that creating robots is a challenge, but sometimes there’s no room for creativity. “We are very project-oriented; however, we would like to have more time for our own creations and to explore ideas ‘outside the box’. INESC TEC, as part of a funding programme for internal projects – Seed Projects -, already allows us to explore some ideas. For instance, we’ve been investing in quadruped robots – which is something that can have potential, in areas like surveillance. The best-case scenario? To explore the exoskeletons area”.

It is true that we do not yet have humanoid robots to guide us on a visit – like the one we made to iiLab; but we should keep dreaming of a future where robots will no longer be simple machines. On the way out, we can only think of one sentence: “Hasta la vista, baby”.

News, current topics, curiosities and so much more about INESC TEC and its community!

News, current topics, curiosities and so much more about INESC TEC and its community!