One of the world’s largest and most prestigious robotics conferences, IROS (International Conference on Intelligent Robots and Systems), took place this year, in China (late October). INESC TEC was represented by four researchers who presented five papers at this event, which gathered more than 8,000 participants from across the globe.

André Gonçalves, Artur Cordeiro, Maria Lopes, and António Oliveira were the four scientists representing INESC TEC at IROS 2025, although many other Institute researchers contributed to the presented work. Their research covered a wide range of topics: from robotic technologies supporting the rehabilitation of stroke patients, robots that learn to recognise and manipulate new objects autonomously, new approaches for automating the unloading of shipping containers, to underwater applications for identifying and selecting points of interest.

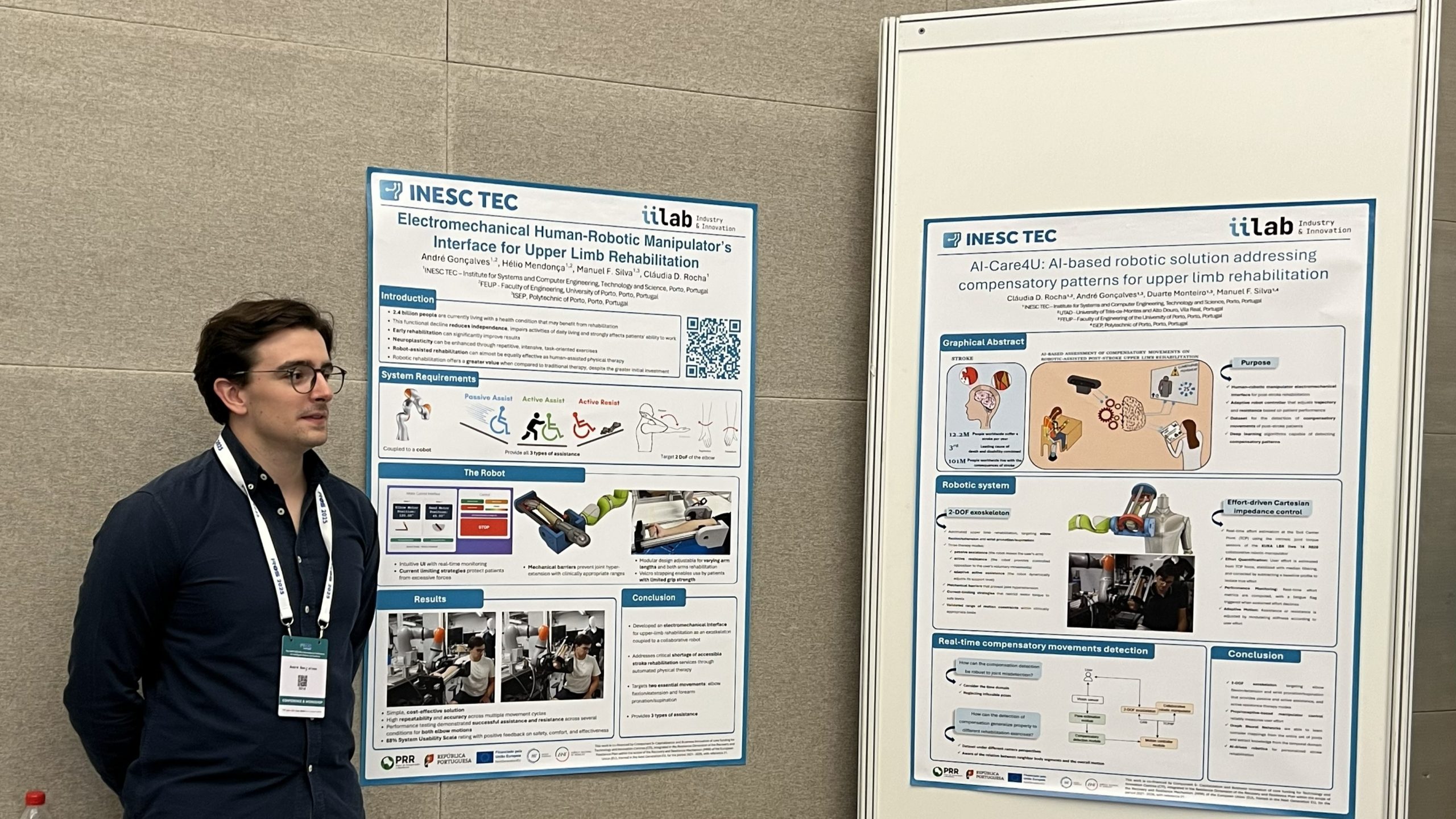

André Gonçalves, who developed his master’s thesis at INESC TEC, presented a two-degree-of-freedom exoskeleton designed by the Institute to assist upper limb rehabilitation in stroke patients. The device supports elbow and wrist movements, and experimental tests confirmed that it enables several therapy modes – passive and active assistance, and active resistance.

“This technology has the potential to improve the quality and efficiency of physical rehabilitation, allowing for more personalised, safe, and accessible therapies.

It focuses on safety, comfort, and individual adaptation, reinforces the social and clinical relevance, and paves the way for integrating robotic solutions into rehabilitation centres – thus promoting the independence and quality of life of people with physical limitations caused by strokes”, said André Gonçalves. The work was developed with Hélio Mendonça, Manuel Silva, and Cláudia Rocha under the AICare4U, a seed project designed, launched, and funded by INESC TEC (more info about the project here).

In another study within the scope of the AICare4U, André presented a research work led by Cláudia Rocha, which combines the exoskeleton with adaptive control of a collaborative robotic manipulator to optimise the rehabilitation process. While the first study focused on the engineering and validation of the system, this second one integrates AI and motion analysis, creating an intelligent robotic solution for motor rehabilitation in stroke survivors. However, both cases still lack technical validation as a single solution – the robotic rehabilitation system includes the exoskeleton, the intelligent control of the robotic manipulator and AI integration.

After a stroke, many patients face limitations in the movement of their upper and lower limbs; to perform daily tasks, they often develop compensatory movements – that is, alternative strategies in which other parts of the body substitute the natural movement of the affected limb. In the case of the work developed by INESC TEC, the focus was solely on the upper limbs. “Although these patterns temporarily help with task execution, they can become consolidated and hinder long-term functional recovery if not corrected during rehabilitation,” explained Cláudia Rocha.

In this sense, the team of scientists – Cláudia Rocha, André Gonçalves, Duarte Monteiro, and Manuel Silva – developed an exoskeleton and coupled it with a KUKA LBR iiwa robotic arm to estimate, in real time, the force exerted by the patient and automatically adjust the level of assistance or resistance according to the effort made.

The team is now committed to advancing to the next phase, where they will integrate AI techniques capable of automatically detecting compensatory movements by analysing the patient’s posture in real time. “This information will allow the robot’s behaviour to be dynamically adjusted, promoting more precise, personalised, and effective rehabilitation, contributing to a more natural and lasting motor recovery,” the researchers explained.

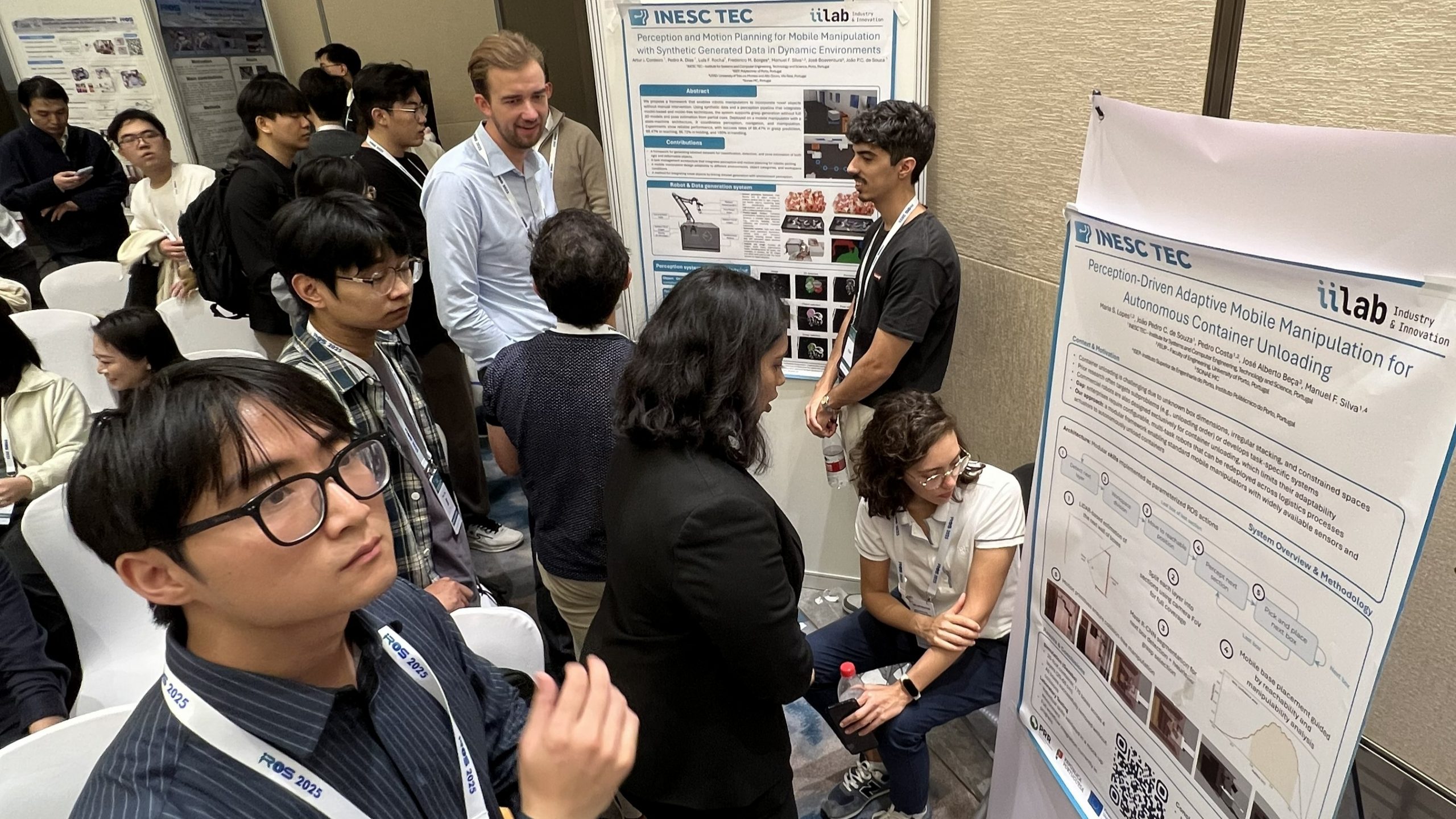

Meanwhile, Artur Cordeiro presented an advanced solution for mobile robotic manipulators, capable of identifying and interacting with objects of different shapes and materials – stiff, regular, irregular, and flexible – in real, dynamic environments like industrial, ocean, aeronautical, and logistics settings. “The system combines analytical methods and machine learning techniques to detect objects, estimate their position, and automatically calculate the best way to grasp them, ensuring stable manipulation,” the researcher mentioned.

One of the main goals of this work, developed under the Produtech R3 project, was to enable the automatic integration of new objects without the need for manual intervention. “To achieve this, a synthetic data generator was created to generate training data with the necessary annotations so that the system can learn to recognise and manipulate new objects, even those it has never seen before,” explained Artur Cordeiro, who developed this work with João Souza, Luís Rocha, Manuel Silva, and José Boaventura.

The framework was tested in various environments, as previously described, and the results showed consistent and high performance across all stages of the manipulation process, proving that this approach can be robustly applied in complex and dynamic scenarios, where the diversity of objects and conditions poses a constant challenge to traditional robotic systems.

Still within the scope of the Produtech R3 project, Maria Lopes presented the research conducted by INESC TEC to automate the unloading of shipping containers – a physically demanding task that is difficult to automate due to the variability in cargo size and arrangement. According to the researcher, “most existing solutions are specific to this task, with hardware and software designed exclusively for this purpose, which limits their reuse in other applications.”

To address this, the team of scientists – Maria Lopes, João Souza, Pedro Costa, and Manuel Silva – proposed a modular framework that enables a generic mobile manipulator, equipped only with standard sensors and actuators, to perform unloading operations autonomously. “The system combines real-time perception and adaptive execution, adjusting its behaviour according to task evolution and sensor feedback,” explained Maria Lopes.

The technology was tested in a simulated environment and demonstrated the ability to complete the unloading of an entire container without collisions. Several modules have also been validated in laboratory settings, and the full pipeline is now being tested.

Finally, António Oliveira, who is currently pursuing his PhD at INESC TEC, presented the work focused on the identification and extraction of points of interest in underwater environments for simultaneous localisation and mapping using sonar.

The innovative aspect of this work lies in exploiting the acoustic beam aperture of the sonar to directly model 3D planar surfaces from 2D data, thus overcoming traditional limitations related to the accuracy of locating individual echoes.

The researcher stated that the solution has already been validated with experimental data, both in controlled settings and real-world environments such as hydroelectric dams. “Our goal is to improve the autonomy in underwater robotic systems, where the ability to extract information from the surrounding environment is crucial to achieve precise localisation and enable tasks like inspection and maintenance to be carried out autonomously,” said António Oliveira.

The participation of INESC TEC in IROS 2025 reinforces the Institute’s ongoing national and international research in industrial robotics, healthcare robotics, and autonomous systems. The diversity of societal areas covered by the presented work highlights INESC TEC’s ability to transform scientific knowledge into concrete solutions that have a real impact on society.

The researchers mentioned in this news piece are associated with INESC TEC, FEUP and IPP-ISEP

News, current topics, curiosities and so much more about INESC TEC and its community!

News, current topics, curiosities and so much more about INESC TEC and its community!