INESC TEC has developed a demonstrator that showcases what the next generation of connectivity could look like: walls, windows or furniture capable of helping devices communicate more efficiently. This technology is part of the European project SUPERIOT and has already been successfully tested, opening new possibilities for smart buildings, industrial automation, logistics and highly reliable indoor communications.

The demonstrator “Large-area IoT node/repeater”, integrates a Reconfigurable Intelligent Surface (RIS) capable of “shaping” radio waves and directing them where they are needed, improving coverage for sensors and devices in indoor environments.

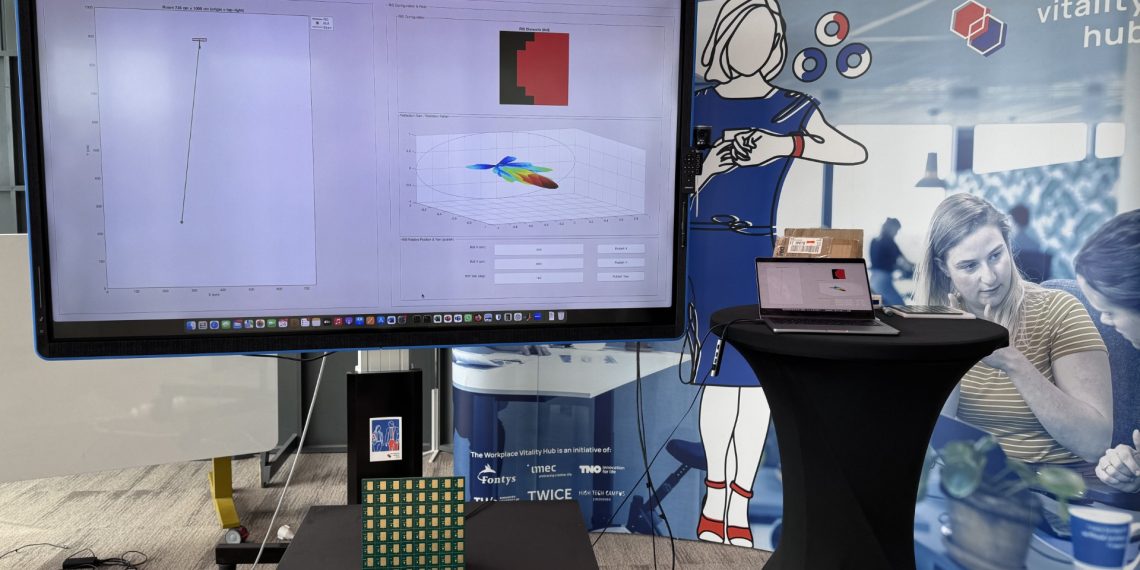

INESC TEC was responsible for the entire solution: from building the intelligent surface and developing the electronics that control it, to the software that enables real-time signal adaptation. In addition, the team developed tools to visualise the operation of the entire system, ensuring that all components communicate correctly with the other systems involved in the project.

“INESC TEC also contributed to the project’s exploratory work on new scalable RIS technologies, including transparent surfaces based on glass and reconfigurable elements based on memristors (i.e., components that ‘store memory’ without requiring constant energy consumption),” explained INESC TEC researcher Luís Pessoa.

The prototype was demonstrated and tested at the Vitality Hub in Eindhoven, the Netherlands, and the results showed that the RIS can adapt within fractions of a second to the movement of a device, redirecting the signal to ensure more stable and accurate communications. The system is modular, meaning that multiple units can be interconnected to cover larger areas – an especially useful feature in environments where many IoT (Internet of Things) technologies coexist, such as industrial facilities, logistics centres or smart homes. In the future, these surfaces may be integrated into walls, ceilings, furniture or even windows.

“Integrating intelligent surfaces directly into building materials avoids the need to install additional equipment and improves the coverage and reliability of communications in complex spaces. At the same time, investing in printed, low-power solutions makes it possible to produce these surfaces at low cost and with a reduced environmental impact. These advances pave the way for integrating RIS directly into architectural materials or everyday objects, with strong potential for technology transfer,” said Luís Pessoa.

Unlike traditional repeaters, these surfaces operate with almost no energy consumption and take advantage of the physical environment instead of requiring additional antennas or cabling. This makes the technology not only innovative but also aligned with the sustainability-driven vision underpinning the SUPERIOT project.

“The RIS operates in a passive, reconfigurable way, with much lower energy consumption than any conventional active repeater and incorporates sustainable materials. This opens the door to fully printed, disposable or recyclable IoT nodes with a low environmental impact,” the researcher added.

With this demonstrator completed and validated, INESC TEC has confirmed that the technology is reliable, scalable and easily adaptable to different contexts. This approach reduces risk, accelerates technology transfer and positions Portuguese research at the forefront of developing solutions that can reach the market more rapidly.

The SUPERIOT project concludes in late 2025.

The researcher mentioned in this news piece is associated with INESC TEC and the Faculty of Engineering of the University of Porto

News, current topics, curiosities and so much more about INESC TEC and its community!

News, current topics, curiosities and so much more about INESC TEC and its community!