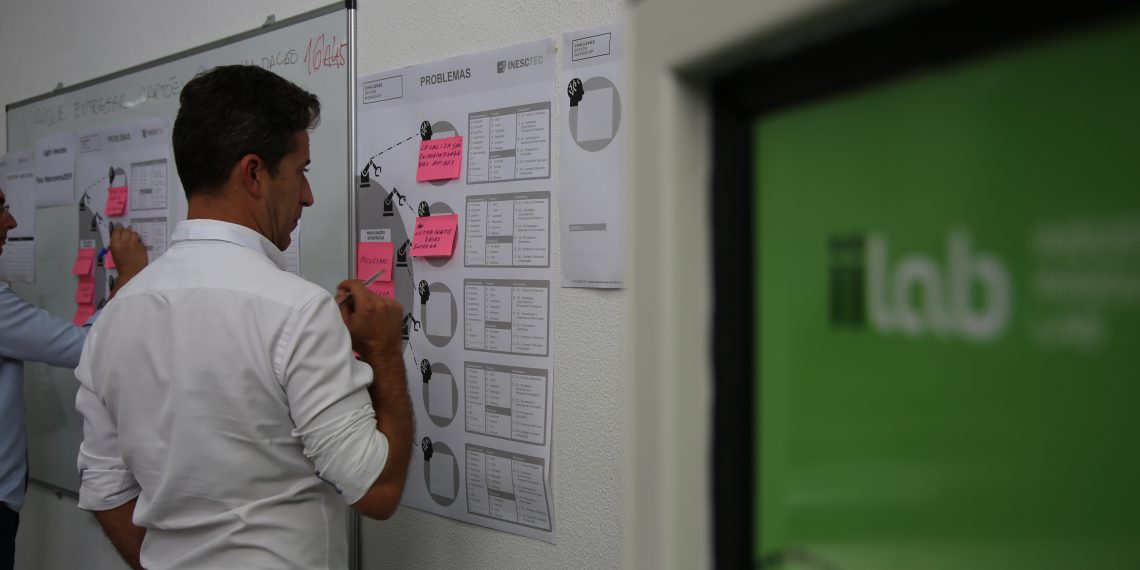

Close to 40 entrepreneurs and managers, representatives of technology demonstrators and researchers from the scientific and technological ecosystem participated in the innovation workshops promoted within the scope of the SAP 4.0 project; the initiative took place at INESC TEC’s iiLab – Industry and Innovation Laboratory. The project is promoted by the Business Association of Oliveira de Azeméis (AECOA) and co-promoted by the Business Association of Santa Maria da Feira (AEF), with INESC TEC participating as technological partner.

The major themes addressed were the definition of opportunities and challenges of the i4.0 digitalisation process; knowledge and testing of i4.0 digital solutions; and the processes and tools for designing strategies for digital transformation. The workshops were promoted within the scope of the project SAP 4.0 – AS-IS characterisation and strategic roadmap design within the scope of Advanced Production Systems. The sessions, attended by companies from the region of Entre Douro and Vouga, aimed to support the industrialists of said geographical area in the development of a i4.0 strategic technological plan.

Laboratories: from theory to practice

Starting from the challenges already identified by companies when carrying out a diagnosis to characterise the i4.0 digital maturity level and the economic context of the region, developed by INESC TEC, the participants were able to discuss the opportunities and challenges of companies throughout their digital transformation process.

“Alongside this reflection, the participants had the opportunity to meet and experience, in our Industry and Innovation Laboratory, i4.0 technologies and success stories, with potential application to their businesses”, explained the researchers of INESC TEC, Alexandra Xavier, Alípio Torre, Daniela Silva, Filipe Ferreira, Pedro Senna and Rui Rebelo.

Among the technology demonstrations, it’s worth mentioning collaborative robotic systems focused on human-machine interaction (developed by INESC TEC’s Centre for Robotics in Industry and Intelligent Systems – CRIIS), mobile pick and place handlers (developed by CRIIS and INESC TEC’s Centre for Enterprise Systems Engineering – CESE), production planning and scheduling systems (presented by CESE and the company softi9), Digital Twin (presented by the company Infinite Foundry), real-time production management platforms (presented by the company proGrow) and augmented reality solutions (presented by the company KIT-AR).

According to INESC TEC researchers, the companies were also challenged to design co-creation solutions in robotics and automation and information systems, as well as their implementation strategy.

“This is a very ambitious project”, stated the heads of the promoting associations, the executive director of AECOA, António Pinto Moreira, and the president of the AEF Board, Alferes Pereira. Considering that this programme aims to “define an i4.0 technological roadmap for all sectors of the Advanced Production Systems”, António Pinto Moreira emphasised the importance of the tech partner’s role: “It is a privilege to rely on INESC TEC, a reference partner of the National Technological and Scientific System, in terms of know-how and scientific and technical experience, thus contributing to the success of this programme”. The coordinator even highlighted the Innovation Laboratories, carried out in iiLab, where it was possible to put into practice all the goals of the project.

The SAP 4.0 project is financed by the Portugal 2020 programme, under the Northern Regional Operational Programme (€411,022.67) – with €349,369.27 granted by the European Regional Development Fund (ERDF).

News, current topics, curiosities and so much more about INESC TEC and its community!

News, current topics, curiosities and so much more about INESC TEC and its community!